IPEEC Selects Energy Conservation Project Using LNG Cold Energy For International Top Ten Best Practices

2016.08.22

Mitsui Chemicals, Inc.

Osaka Petrochemical Industries, Ltd.

Osaka Gas Co., Ltd.

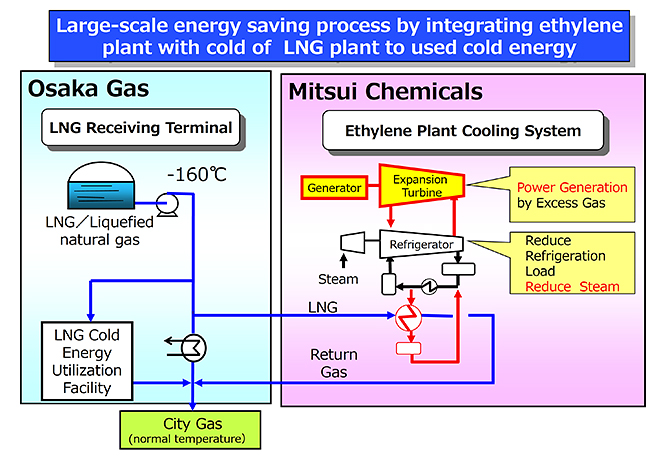

Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: Tsutomu Tannowa; “Mitsui Chemicals”) and Osaka Petrochemical Industries, Ltd. (Tokyo; President:Kazuto Okamoto; “OPC”), a wholly owned Mitsui Chemicals subsidiary, announced that its large-scale energy conservation joint project with Osaka Gas Co., Ltd. (Osaka; President:Takehiro Honjo; “Osaka Gas”), which integrates an ethylene plant with a LNG (liquefied natural gas) plant to use cold energy, was selected by the International Partnership for Energy Efficiency Cooperation (“IPEEC”) for its first list of International Top Ten Best Practices in energy efficiency.

Operations for this world’s first energy-saving process using LNG-generated cold energy on a large-scale at an ethylene plant commenced in October 2010. The three companies will continue to pursue reducing environmental impact of production activities and greenhouse gases (GHG) while continuing to develop and expand better energy-saving technology.

IPEEC Top Ten Technologies and Practices

Against a backdrop of rapidly increasing global warming associated with growing energy demands and an urgent need to disperse energy efficiency information and policies to conserve energy, IPEEC was established in 2009 by the G8 (Group of 8) with the aim of incorporating major energy-consuming non-IEA (International Energy Agency) countries into the international framework of energy conservation. (Current IPEEC members: Australia, European Union, Italy, South Africa, Brazil, France, Japan, South Korea, Canada, Germany, Mexico, Britain, China, India, Russia, and the United States)

IPEEC’s first international Top Ten lists documenting the best available technologies and practices to improve energy efficiency are based on input from the countries participating in the task group — China, Australia, Japan and the United States. Rigorous methodology designed specifically for the Top Ten task group was applied to the information to develop the first international Top Ten list of this ongoing global collaborative project of which the top ten best practices (“BP”) and best available technologies (“BAT”) were announced at the June 27, 2016 IPEEC policy meeting in Beijing and incorporated as a leading program at the G20 Energy Ministers Meeting on June 30th.

Integrating ethylene plant with LNG plant to used cold energy for large-scale energy-saving

To transport and store natural gas, it is liquefied by cooling it to -160°C. Liquefied gas is a good source of cold energy. During its liquefied state, LNG emits boil off gas which has auto-refrigeration properties. When returning LNG to its gas state, it continues to retain superior cooling abilities.

At Mitsui Chemicals’ Osaka Works OPC ethylene plant, after thermal decomposition of naphtha (crude gasoline) at high temperatures, base materials such as ethylene and propylene are separated and purified by cooling the cracked gas. By efficient use of LNG cold energy from the adjacent OPC ethylene plant of Osaka Gas Senboku Works, a significant reduction in CO2 emissions was possible.

This innovative energy saving process received the FY2011 "Energy Conservation Award" of the Minister of Economy, Trade and Industry Award from the Japanese Energy Conservation Center.

OPC LNG cold energy facilities