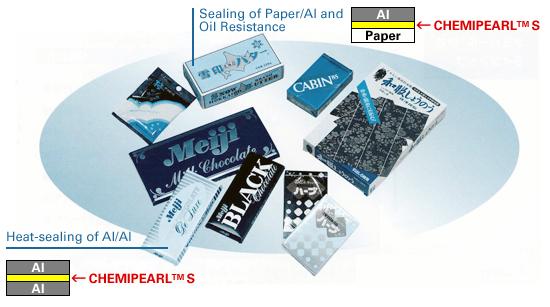

Additives for printing ink, heat sealants

CHEMIPEARL(development article)

Polyolefin-based Aqueous Dispersion

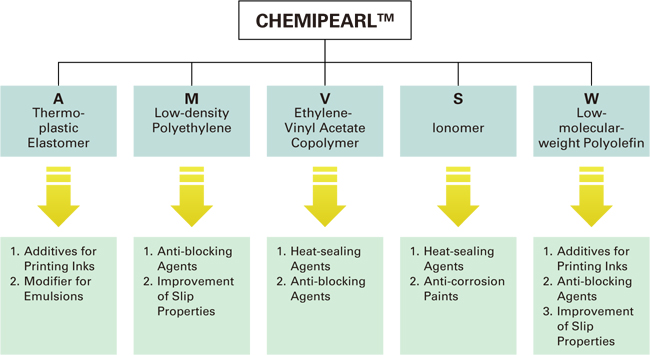

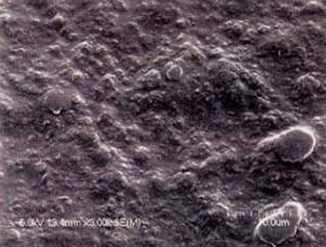

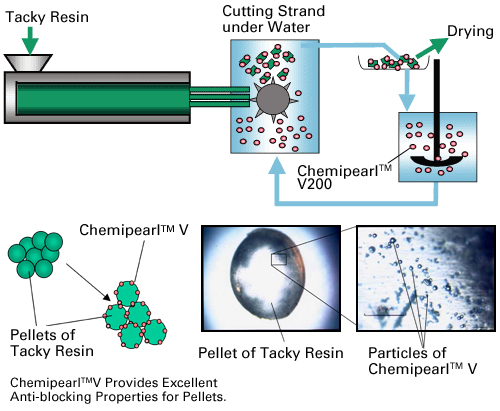

CHEMIPEARL™, which is made of fine particles of polyolefin, uses Mitsui Chemicals’ unique technology and is an environmentally friendly aqueous dispersion that does not use emulsifying agents or organic solvents (except for some grades and Products in Development).

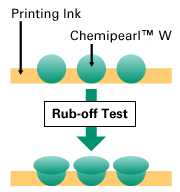

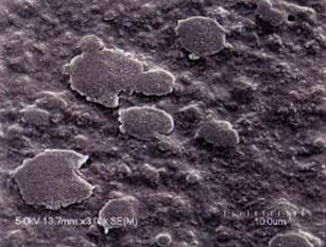

Abrasion resistant Improved slip properties Anti-blocking agent Superior application properties Outstanding heat-sealing properties Hygienic qualities

Applications detail

Applications

Characteristics

- Basic information

- Details of Characteristics

- Details of Applications

BASIC INFORMATION

New Chemipearl™ is polyolefin dispersion using our proprietary technology.

New Chemipearl™ has no chloric material or solvents.

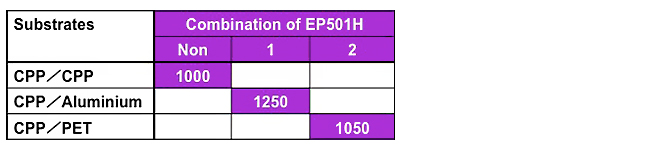

New Chemipearl™ has improved adhesive strength for a variety of substrates.

PDF Catalog

Contact Us

Coatings & Engineering Materials Division