Mitsui Chemicals Group's Bio-Polypropylene Adopted for Project Commissioned by Ministry of the Environment

Industrial-level-trial set to begin to expand the bio-based plastic market with the first of its kind technology

2019.09.26

Mitsui Chemicals, Inc

Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: Tsutomu Tannowa) is collaborating with Kaisei Inc. (Murakami, Niigata Prefecture; President & CEO: Tadahiro Toyama) to commercialize bio-polypropylene (bio-PP).

Japan's Ministry of the Environment has adopted Mitsui Chemicals' bio-PP pilot project to build a system to recycle plastic and other resources in support of a carbon-free society*1 – this coming as part of Japan's efforts to reduce greenhouse gas (GHG) emissions. Hereafter, Mitsui Chemicals is conducting the world's first bio-PP industrialization demonstration test, and plans to conduct multifaceted evaluations of technologies, quality, economic efficiency, and environmental impact such as GHG reduction. Solving these issues, Mitsui Chemicals Group will consider commercialization of bio-PP (production will start in 2024 at the shortest). Our group will work on this project as part of the expansion of Blue Value™ products (environmental contribution value products) based on our climate change policy and plastic strategies.

Key Points

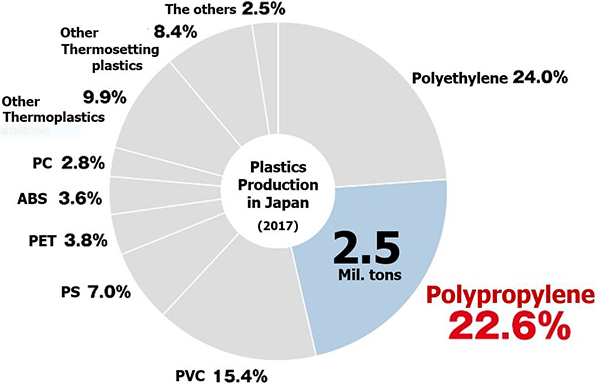

We aim to commercialize bio-PP, which has yet to be produced from biomass unlike other major resins

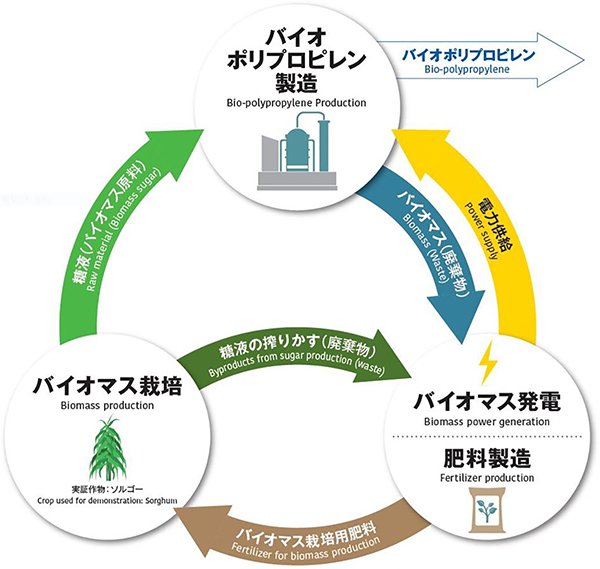

We will build a circular model throughout the manufacturing supply chain to significantly reduce CO2 emissions.

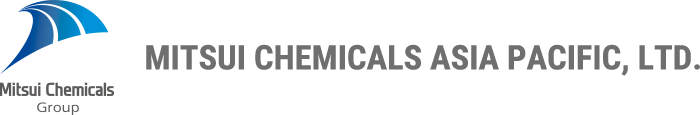

Polypropylene has a wide range of applications, spanning automobile-parts to medical care products, home appliances, housing and food products. The Polypropylene plays an essential role in our lives and accounts for more than 20 percent of the plastic produced in Japan. However, due to technical difficulties, Production of polypropylene from biomass has not been established at the industrial level.

Conventional plastics are produced from fossil resources that have been stored underground for hundreds of millions of years, while bioplastics*2 are primarily derived from plants. Since plants absorb CO2 from the atmosphere to grow, they offer a more effective way to reduce CO2 emissions, thus helping to mitigate global warming. Bio-PP derived from plants is a product expected to contribute to sustainable society.

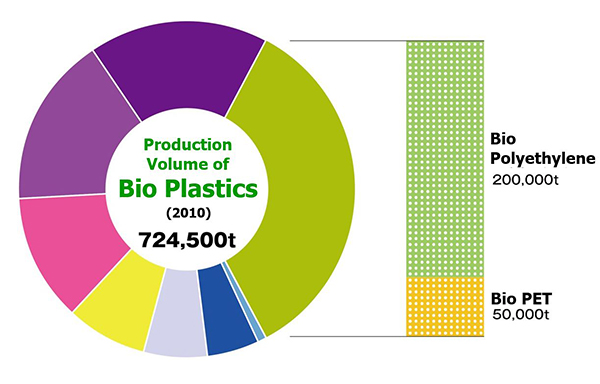

The new production method being attempted for commercialization sees various biomass mainly non-edible plants are fermented to produce isopropanol (IPA), which is then dehydrated to obtain propylene in a first-of-its-kind IPA method. Compared to other biomass production approaches studied by other companies thus far, this one could prove to be a more cost-effective way to manufacture bio-PP.

Kaisei Inc. will cultivate biomass raw materials used by Mitsui Chemicals, collect wastes generated from biomass raw materials, and supply electricity to manufacturing facilities and manufactures fertilizers through its effective use. By collaborating with Kaisei Inc., Mitsui Chemicals aims to contribute to society through environmentally friendly action with a circular model that leverages the supply chain.

Mitsui Chemicals is acting proactively through its business activities to address societal issues as it aims to contribute to cohesive society in harmony with the environment, and to achieve sustainable development for both society and the Mitsui Chemicals Group.

Overview of the Initiative

| Project name | Bio-PP pilot project |

|---|---|

| Applicant | Mitsui Chemicals, Inc. |

| Partner | Kaisei Inc. |

| Trial period | Adopted as a three-year project beginning in fiscal 2019 |

*1As it is essential to switch from petroleum-derived materials to renewable resources such as biomass and biodegradable plastic, and to create a CO2-conserving recycling system for used waste plastic, this initiative by the Ministry of the Environment will support a carbon-free society by accelerating the construction of resource recycling systems for plastics and other materials. This project will run trials for switching to renewable resources as a substitute for petroleum-derived plastic and introduce them to the public, as well as for building recycling processes for plastic and other materials. Supervision: Office of Recycling Promotion, Policy Planning Division, Waste Management and Recycling Department, Ministry of the Environment.

*2Polymeric materials (plastics) obtained through chemical and biological synthesis, and whose raw materials contain substances derived from renewable organic resources. (Source: Japan BioPlastics Association